How Australia killed it’s manufacturing industry

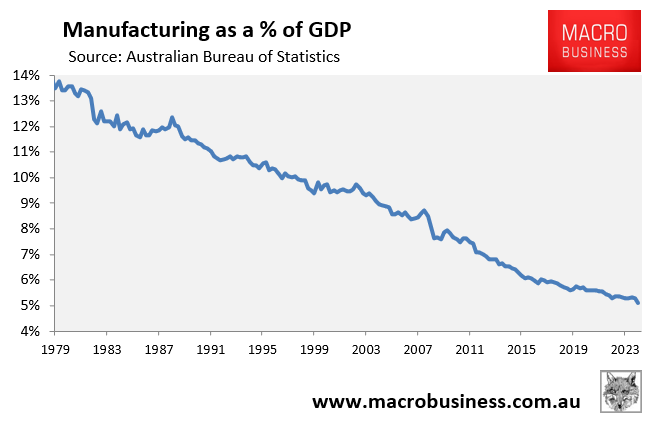

Australia’s manufacturing industry is in terminal decline, falling to only around 5% of the economy in 2024, down from around 14% in the late 1970s.

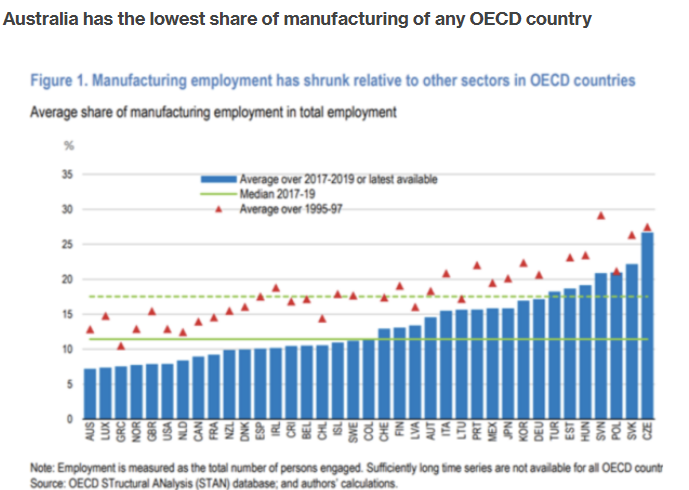

Australia has the lowest manufacturing share in the OECD.

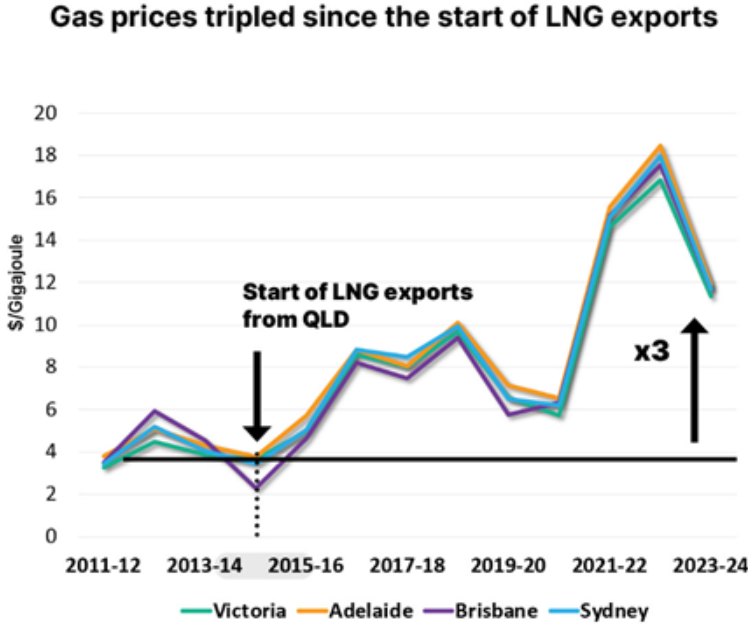

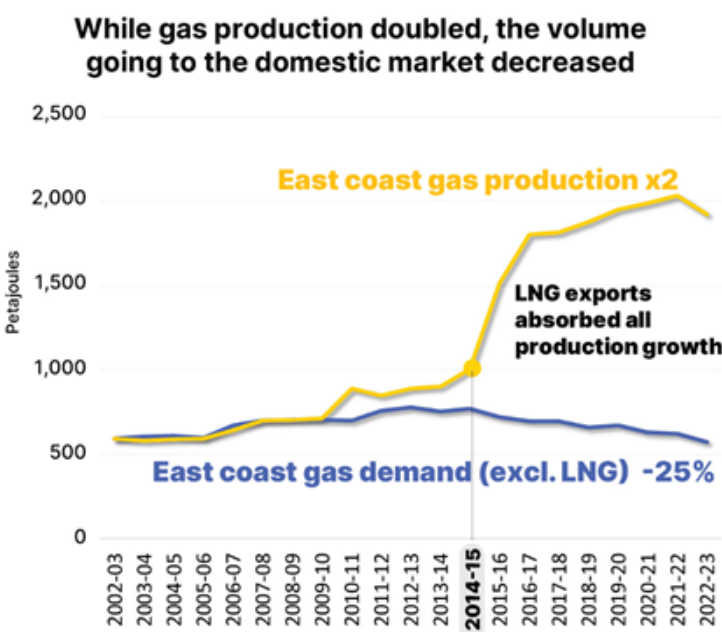

One of the recent causes of Australian manufacturing decline has been soaring energy costs on the East Coast of Australia.

East Coast gas prices have tripled since liquified natural gas (LNG) exports commenced out of Gladstone eleven years ago, which has driven corresponding rises in electricity prices.

Around 25% less gas has been supplied to the East Coast domestic market, despite gas production doubling over the past decade.

According to ASIC, around 1400 manufacturers have collapsed since 2022-23.

Over the last few years, major Australian manufacturers have downsized or closed completely.

Incitec Pivot slashed fertiliser output in response to increased energy prices. It closed its Gibson facility in Queensland in 2022, affecting 170 employees. Incitec’s Geelong fertiliser company also shuttered last year, costing 40 jobs.

Incitec Pivot Fertilisers’ Phosphate Hill factory continues to harvest phosphate rock and manufacture ammonium phosphate fertilisers. However, this is also being reviewed from a strategic standpoint.

Dyno Nobel sold Incitec Pivot for a fire sale price on Monday due to high gas prices. However, Dyno Nobel CEO Mauro Neves noted opportunities in Western Australia, where gas is cheap due to its domestic reservation policy.

“You have a successful energy policy [in WA], you can support local manufacturing”, Neves said.

“If you don’t, we end up losing manufacturing towards a very liquid global market”.

Qenos, Australia’s only major plastics plant, closed down last year due to expensive energy costs.

Oceania Glass, Australia’s only architectural glass firm, closed down in March 2025 after 169 years of operation.

Oceania Glass required a significant amount of energy, particularly gas, to power its 2000-tonne furnace at the heart of its Victorian operations. As East Coast gas and energy prices skyrocketed, the company’s profitability plummeted alongside its viability.

As a result, Australia will need to purchase all of its glass and plastics from China.

Orica, the world’s largest manufacturer of mining explosives, chemicals, and agricultural fertilisers, and BlueScope Steel have threatened to reduce or close their Australian operations due to rising energy costs.

Orica’s CEO Sanjeev Gandhi says there are far better opportunities in the United States, where energy is cheaper and policy is manufacturing-friendly.

“Just look at what’s happening in the United States. They are pro-manufacturing, they are pro mining, they are for infrastructure. All of that is where Orica plays and they’ve got very, very cost competitive energy prices”, Ghandi said.

“So given a choice, my incremental dollar would always go first to the United States and Australia doesn’t come on the top of the list”.

“If we can get enough gas supply at cost competitive prices, my next dollar comes into Australia… So it’s all a matter of getting the policy right”.

“If you want to have a future made in Australia, manufacturing very clearly needs cost competitive energy, electricity prices, cost competitive natural gas, and enough availability of gas and obviously skilled labour”.

“If we can address those policy issues, I’m very, very confident that manufacturing will not just survive and thrive in this country, but then we, as manufacturing owners in the country, will be encouraged to do more in Australia”, he said.

BlueScope, which supported the Coalition’s domestic gas reservation policy, warned that the situation has become dire for manufacturers.

“I think the supply equation on the east coast is a challenge and continues to be a challenge and it absolutely needs to be addressed”, BlueScope chief financial officer David Fallu said.

“There needs to be a targeted approach to how policy can support industry”.

In March 2025, Manufacturing Australia, which represents large East Coast gas users, called for a domestic reservation scheme, modelled on Western Australia. It also warned of price hikes if planned LNG import terminals come online.

“In the long term, [LNG imports] are likely to do more harm than good, and Australia will never regain its energy cost advantage—nor secure the future of manufacturers that need competitively priced gas—if we entrench import parity pricing”, Manufacturing Australia chief executive Ben Eade wrote in The Australian.

“Australia doesn’t need imported gas. We should develop and reserve domestic gas for manufacturers and local customers, rather than pursue solutions that entrench import parity pricing. What’s required is political courage to ensure our abundant natural resources benefit the entire economy, not just the export sector”, Eade said.

The Energy Users Association of Australia, whose members include Brickworks, added that it was unthinkable that one of the world’s biggest LNG exporters was contemplating importing LNG.

“It’s a significant failure of policy, planning and production. It is like importing sand into the Sahara”, EUAA chief executive Andrew Richards said.

The reality is that if East Coast Australia begins importing LNG, the gas price will rocket from around $12 a gigajoule currently to import parity prices of around $20 a gigajoule.

Electricity prices will also soar given gas’s vital role in firming and as a marginal price setter in the wholesale electricity market.

More Australian manufacturers will be driven out of business by high energy costs, and the only ones that will survive will be those that are non-tradable, like bricks, or reliant on government subsidies.

Domestically made building material costs will also rise, making it more expensive to build homes and harder to meet housing supply targets.

Put simply, the Albanese government must emulate the Coalition’s gas reservation policy. Otherwise, Australia faces soaring energy costs, higher inflation, and further deindustrialisation.